-

Below-Grade Waterproofing

Refers to waterproofing applied below ground level that comes into contact with a building or structure-If you have a below ground deck or a basement, you’re going to need to consider a below grade waterproofing coating. Below-Grade area are in constant contact with water as you may already know. Basements are extremely vulnerable to moisture or flooding. Without waterproofing, you could deal with major floor deterioration issues down the road that becomes expensive to fix.

-

Cold Waterproofing

- Cold applied waterproofing is the use of a liquid waterproofing system without the requirement of heat, Being applied by trowel, a squeegee, spray or roller, it greatly reduces the chance of moisture and water trapped in concrete. With cold-applied waterproofing, you can build a continuous membrane for waterproofing integrity.

-

Hot Applied Waterproofing

- Hot rubberized waterproofing systems are fluid-applied membranes that consist of a blend of asphalt and modified rubber polymers containing mineral stabilizers. This waterproofing system allow for creating monolithic membranes that can cover a large surface area. Both systems can be applied to vertical and horizontal surfaces. Used on Flat roofs, Parking structures, Planters, Pool decks and Amenities Deck.

-

Window Sealants

-

- Are used to seal from window frame to the structure of the building. There are 5 points of window sealants.

- Subcaulking- The subcaulking is your usual main seal from window frame to structure.

- Beauty Bead- Is to keep water from getting in between the stucco and window perimeters.

- Metal to Metal and Miders-are your hairline metal joints on area's where a metal meets another.

- Glazing- is sealing from glass to metal or glass to glass.

-

-

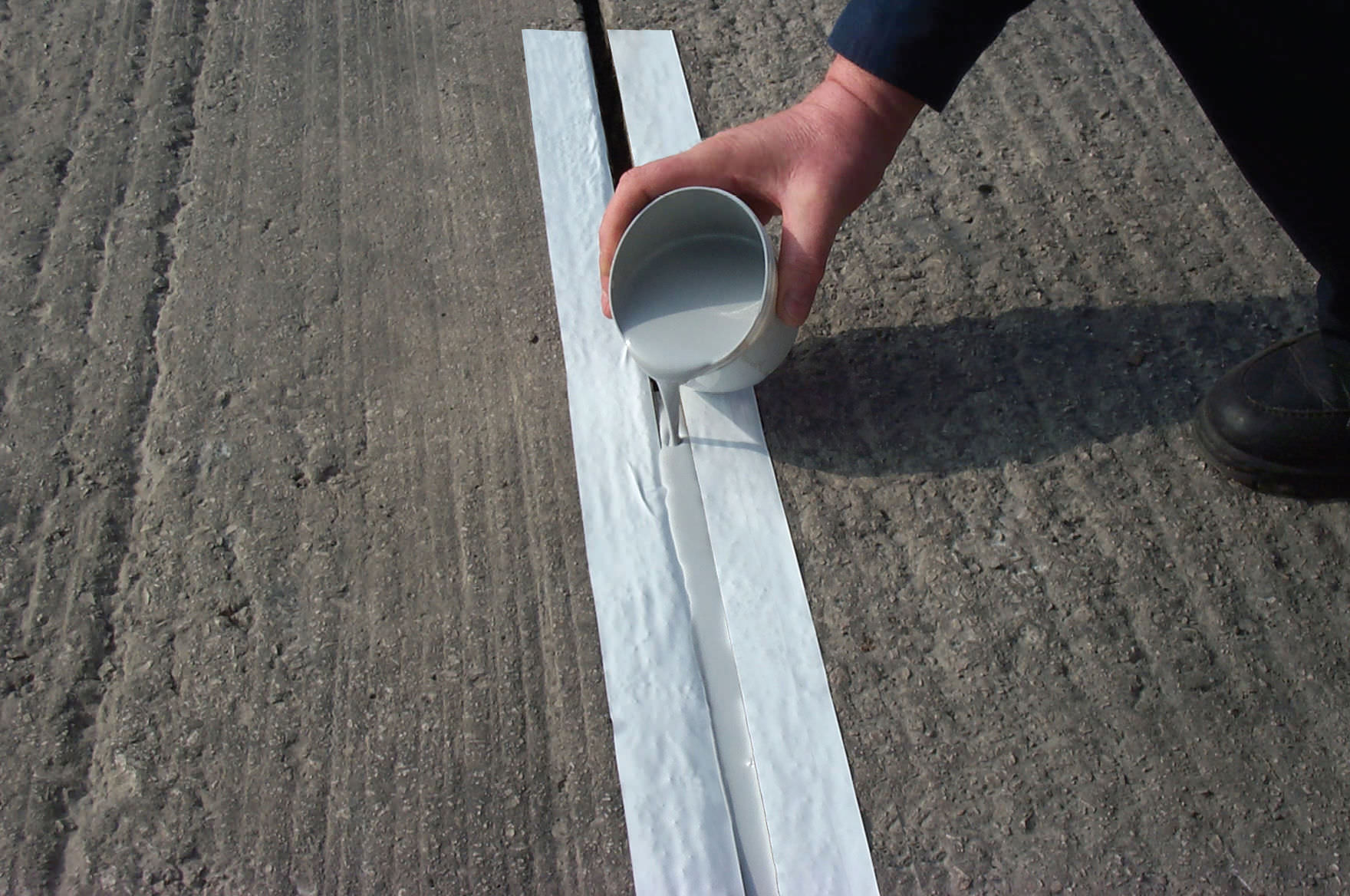

Joint Sealants

- Structures and buildings rely on joint sealants to protect from water intrusion and moisture. Its used to seal joints and openings (gaps) between two or more substrates and is a critical component for building designs, construction and longevity of the buildings. Poor movement capabilities, poor joint design, Reverted, improper installation or Expired sealants all require removing existing sealants.

-

Epoxy Floor Coatings

-

- Epoxy is most often applied to protect and beautify concrete floors, but it is more versatile and complex than that. It has a long lifespan, low maintenance and has superior hardness. Epoxy flooring is used in residents, retail or industrial floors, as well as commercial spaces.

- Decorative Flakes and Quartz floor Coatings- Is an anti-slip flooring surface that is attractive, helps enhance both beauty and safety, has different colors, color blends, textures, and sizes. Can be used at a residence, retail, industrial floors, as well as commercial spaces, it leave the area with a vibrant and a resilient surface.

-

-

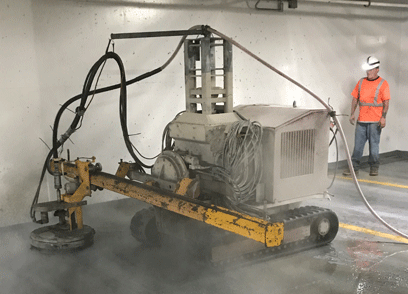

Tile and Waterproofing Removal-

- Properly removing waterproofing with High powered Commercial Concrete Grinders are used to first break up the Waterproofing Membrane as it is usually a thick rubber. The waterproofing is then removed with PCD blades on the grinders and at the same time leaves the proper surface profile.

Professionalism Above Reproach

Guaranteeing our work and upholding our promises